A Comprehensive Solution Of ZS-FAL32-10 Bottled Integrated Line

ZONESUN Technology Limited is a leading manufacturer of automatic packaging machinery, specializing in filling machines, capping machines, labeling machines, and large automatic production lines. We are dedicated to providing our customers with customized solutions that meet their unique packaging needs.

The ZONESUN ZS-FAL32-10 Bottled Water Packaging Integrated Line is a turnkey solution designed for efficient and streamlined bottled water production. Let’s delve into its features, manufacturing process, and customization procedures.

Features and Components:

-

Water Treatment Unit:

- Raw Water Tank + Raw Water Pump: Stores and transfers untreated water.

- Silica Sand Filter + Active Carbon Filter + Sodium Ion Exchanger + Precision Filter + Security Filter: Removes impurities (larger particles, organic matter, dissolved salts, smaller particles, and remaining impurities).

- Reverse Osmosis (One Level) System: Separates dissolved solids and impurities using pressure.

- UV Sterilizer: Ensures water is free from harmful microorganisms.

- Finished Water Tank + Pure Water Pump: Stores treated water before bottling.

-

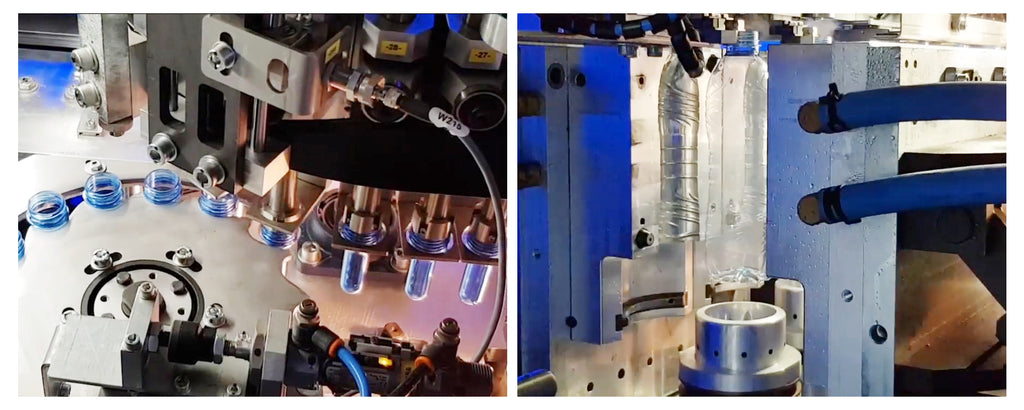

Blow-Molding Unit:

- Creates the bottles themselves.

-

Rinse-Fill-Cap Unit:

- Cleans, fills, and caps the bottles with water.

-

Labeling Unit:

- Labels the bottles with branding and essential information.

-

Shrink Wrapper Unit:

- Securely wraps bottles in plastic film for transport and distribution.

Advantages:

- Comprehensive Solution: Covers all aspects of bottled water production.

- Efficient Design: Minimizes customization needs.

- Easy to Use: Ideal for companies seeking quick production startup.

- High-Quality Water: Ensures clean and safe water for consumption.

Manufacturing Process:

- Water Treatment: Raw water undergoes filtration, reverse osmosis, and UV sterilization.

- Bottle Creation: The blow-molding unit shapes PET bottles.

- Filling and Capping: Rinse-fill-cap unit cleans, fills, and seals bottles.

- Labeling: Bottles receive branding and information labels.

- Wrapping: Shrink wrapper unit securely wraps bottles.

Customization Process:

- Bottle Size and Shape: Adjust blow-molding parameters for different bottle sizes and shapes.

- Material Compatibility: Customize components based on the type of material (PET, glass) used for bottles.

- Label Design: Modify labeling unit settings for branding and information labels.

- Production Speed: Adjust filling and capping speed as per production requirements.

In summary, the ZONESUN ZS-FAL32-10 Bottled Water Packaging Integrated Line offers a complete solution for high-quality bottled water production. Its efficiency, ease of use, and minimal customization make it an excellent choice for companies aiming to optimize their operations. Whether you’re a small startup or an established brand, rely on ZONESUN for your packaging needs.