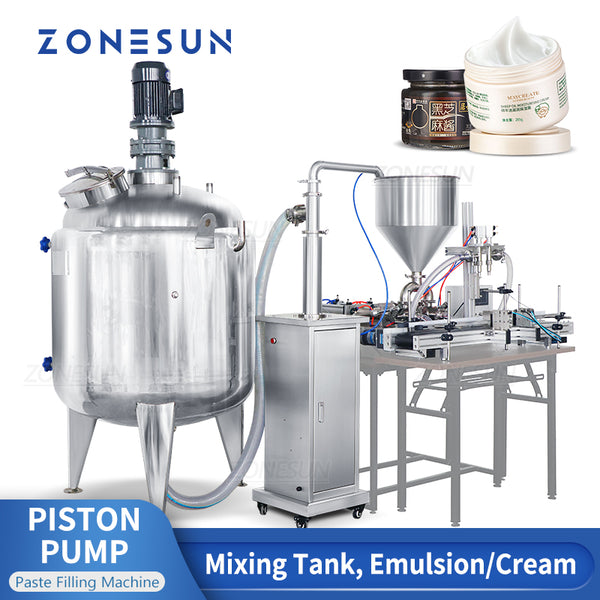

Paste Filling Machine Solutions for Viscous Products

Introduction to Viscous Paste Filling Machines

A viscous paste filling machine is specially designed for high-viscosity and semi-solid materials, accurately filling jars, bottles, tubes, or containers. Compared with ordinary liquid filling machines, it uses a piston pump / rotary lobe pump based system to ensure high precision while minimizing drips and waste.

Key features:

- Stainless steel contact parts, compliant with food and pharmaceutical hygiene standards

- Adjustable filling speed and volume

- Anti-drip design for efficiency and product consistency

- Integration with conveyor lines and automated packaging systems

2. Industries & Typical Applications

Zonesun paste filling machines are widely used for various industries and high-viscosity products:

Food & Sauces

-

Honey, jam, sauces, chocolate paste

Cosmetics & Skincare

-

Creams, lotions, gels, hand creams

Pharmaceutical & Healthcare

-

Medical ointments, gels, high-viscosity liquids

Other Industries

-

Household chemicals, adhesives, and industrial pastes

3. Machine Types & Features

3.1 Semi-Automatic Filling Machines

Ideal for small batches or laboratory/plant production. Flexible operation and low cost.

Features:

- Manual feeding or foot pedal operation

- Easy to set up and clean

- Adjustable filling volume and speed

3.2 Automatic Filling Machines

Designed for continuous production lines with high output and minimal labor. Can integrate with conveyors, cappers, and labeling machines.

Features:

- Continuous automatic filling

- High-frequency stable output

- Customizable for production capacity

4. Core Advantages

All Zonesun solutions offer:

- SUS304/316 stainless steel contact parts for durability and hygiene

- Adjustable filling speed and volume

- PLC/Digital control for easy operation

- Multiple nozzle options for different container shapes

- Modular design for easy maintenance

5. Customer Success Stories

Case 1 | Food Industry – Jam Production

Challenge: Accurate filling of high-viscosity jam

Solution: Fully automatic high-viscosity paste filling machine

Results: Production increased 3–4 times, material waste significantly reduced

Case 2 | Cosmetics Industry – Cream Filling

Challenge: Thick cream requires precise dosing

Solution: Semi-automatic filling machine with adjustable nozzle

Results: Filling accuracy ±1%, production stable

Case 3 | Pharmaceutical Industry – Medical Gel

Challenge: High-viscosity gel must be contamination-free

Solution: Automatic filling machine with cleaning and anti-drip system

Results: Compliant with strict quality standards, smooth production

6. Customer Testimonials

“Using Zonesun’s fully automatic paste filling machine, our production line efficiency improved significantly, especially for high-viscosity products.”

— Client A, Food Industry

“The semi-automatic machine is easy to operate and perfect for small-batch skincare production, reducing our error rate.”

—A Japan Client, Cosmetic Company Production Manager

“The high-viscosity filling machine’s anti-drip design saves cleaning time and increases efficiency.”

— A German Client, Pharmaceutical Production Manager

7. Machine Specification Comparison Table

| Machine Type | Typical Output | Filling Accuracy | Suitable Viscosity | Automation Level | Ideal Use |

|---|---|---|---|---|---|

| Semi-Automatic | 5–20 bottles/min | ±0.5–1% | Low–Medium | Manual | Small batch / lab production |

| Automatic | 20–70 bottles/min | ±0.5% | Medium–High | Fully Automatic | Continuous production line |

| Multi-Head / High Output | 30–100+ bottles/min | ±0.3–0.5% | High | Fully Integrated | Large-scale industrial line |

Note: Parameters such as speed, accuracy, and number of nozzles vary depending on model and configuration.

8. How to Choose the Right Machine

Consider the following when selecting a paste filling machine:

-

Viscosity and properties of your product

-

Required production capacity

-

Container type and size

-

Automation needs (conveyors, cappers, labeling integration)

-

Available space and budget

Our technical team can provide customized recommendations based on your product and production line requirements.

9. FAQ

Q1: What types of containers can be filled?

A1: Bottles, jars, tubes, pails, and other shapes, depending on machine model and accessories.

Q2: Can the machine parameters be customized?

A2: Yes, machines can be configured according to viscosity, container size, and production line requirements.

Q3: How is filling accuracy ensured?

A3: Machines use precise piston or pump systems with digital controls for consistent and accurate filling.

10. Contact Us

For professional advice, quotations, or custom solutions:

📧 Email: sales6@zonesun.com

📞 Phone: +86 189 3431 0866

CTA: Contact us now to get a tailor-made viscous product paste filling solution!