Popular Collection

ZONESUN Filling Machine

Mastering Precision: A Comprehensive Guide to Filling Machines and ZONESUN's Expertise

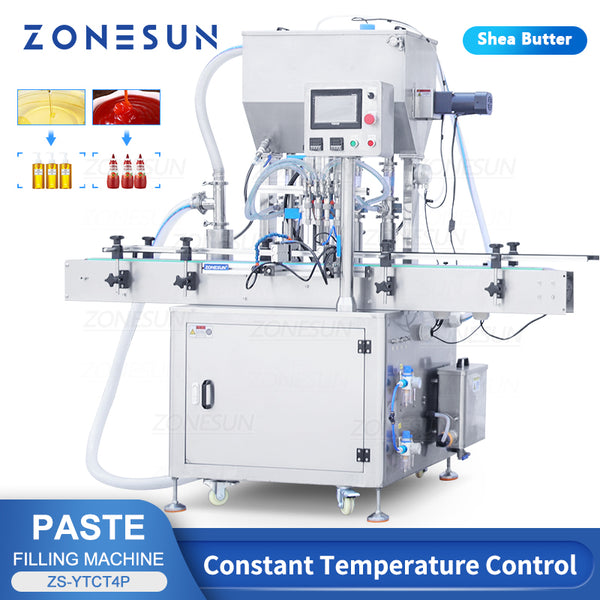

In today's increasingly refined manufacturing and packaging processes, filling efficiency and precision remain paramount for ensuring product quality and production effectiveness. Whether you're handling free-flowing liquids, viscous pastes, or volatile substances, reliable filling equipment is crucial for a successful production line. ZONESUN, specializing in packaging machinery, leverages continuous R&D investment and extensive industry experience to provide global customers with dependable, flexible, and customizable filling solutions, empowering businesses to meet diverse production demands.

What is a Filling Machine?

Filling machines, also known as filling systems or dispensers, are specialized devices used to accurately deliver a set amount of product into a designated container. Whether handling liquids, creams, or semi-solids, these machines play a vital role across industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. By ensuring precise volume control, they help maintain product consistency, reduce material waste, and significantly increase production efficiency. Depending on the product's nature, filling systems can be tailored to handle bottles, jars, tubes, pouches, and various other packaging formats.

Understanding Filling Machine Pump Classifications and Applications

The heart of a filling machine often lies in its pumping system, which dictates its suitability for different product viscosities and filling requirements. Understanding these classifications is crucial for selecting the right filling equipment:

-

Piston Pumps: High-accuracy volumetric filling for liquids, gels, and pastes like sauces, creams, and pharmaceutical syrups.

-

Peristaltic Pumps: Ideal for sensitive or corrosive liquids, preventing contamination; widely used in biotech and pharmaceutical industries.

-

Gear Pumps: Designed for medium to high viscosity liquids such as oils and lotions, offering smooth, pulse-free flow.

-

Diaphragm Pumps: Best for abrasive or hazardous materials like paints and inks; prevents product contact with mechanical parts.

-

Rotary Lobe Pumps: Gentle handling of viscous, shear-sensitive products with particulates, such as fruit purees and yogurt.

-

Gravity Pumps: Cost-effective solution for non-viscous liquids like water and juices, perfume utilizing gravity for filling.

-

Auger Pumps: Ideal for powders and granules like flour, spices, and protein powders. They use a screw mechanism for accurate and consistent filling

Each pump type, whether for a liquid filling machine or a paste filling machine, is optimized for specific product characteristics, ensuring efficient and hygienic operation.

Operational Modes: Manual, Semi-Automatic, and Automatic Filling Machines

Filling equipment comes in various operational modes to suit different production scales and automation requirements:

-

Manual Filling Machines: Operator-controlled, ideal for small-batch production, labs, or startups seeking cost-effective flexibility.

-

Semi-Automatic Filling Machines: A mix of manual and automated operation, boosting efficiency for growing businesses.

-

Automatic Filling Machines: Fully automated for high-volume production, ensuring precision, speed, and minimal human intervention.

Common Materials Handled by Filling Machines

The versatility of filling equipment is evident in the vast array of materials they can process:

-

Liquid Filler: For water, juices, soft drinks, milk, edible oils, sauces, syrups, honey, alcohol, cleaning solutions, chemicals, pharmaceuticals (e.g., eye drops, cough syrup), cosmetics (e.g., toners, perfumes).

-

Pastes & Gels Filler: For creams, lotions, ointments, toothpaste, mayonnaise, mustard, ketchup, jams, jellies, chocolate spreads, butter, paints, caulks, glues, shampoo, conditioner, hand sanitizer, liquid soap.

-

Semi-Solids with Particulates Filler: For Soups, stews, yogurts with fruit pieces, chunky sauces.

-

Powder & Granules Filler: For Flour, coffee powder, protein powder, spices, sugar, salt, baking soda, pharmaceutical powders, detergent powder, tea leaves, fertilizer granules, nutritional supplements.

This broad capability makes filling machines indispensable across numerous industries.

Common Filling Container Types

Filling machines are designed to accommodate a diverse range of container types and sizes:

· Bottles: Plastic (PET, HDPE, PVC), glass (various shapes and sizes) for beverages, pharmaceuticals, cosmetics, and household products.

· Jars: Glass and plastic jars for creams, food spreads, condiments, and powders.

· Pouches/Bags: Flexible pouches for liquids, sauces, pet food, and single-serve products.

· Tubes: Plastic or laminate tubes for toothpaste, ointments, and cosmetic creams.

· Cans: Metal cans for beverages, food, and industrial products.

· Vials/Ampoules: Small glass containers for pharmaceutical injections and diagnostic reagents.

The adaptability of filling equipment to various container formats enhances production line flexibility.

Advantages and Applications of Various Filling Machines

Different filling machine types offer unique benefits, making them suitable for specific applications:

· Volumetric Filling Machines: Offer high accuracy by dispensing a fixed volume of product. Ideal for consistent fills of liquids and pastes, minimizing product giveaway. (e.g., piston fillers for pharmaceuticals).

· Weight Filling Machines: Fill containers to a precise weight, excellent for high-value products or when product density can vary. (e.g., large containers of chemicals or food ingredients).

· Level Filling Machines: Fill all containers to the same visual level, crucial for aesthetic appeal, especially in cosmetic and beverage industries. (e.g., overflow fillers for transparent bottles).

· Vacuum Filling Machines: Used for fragile containers or products that tend to foam. The vacuum draws product into the container, ensuring a clean fill. (e.g., perfumes, alcoholic beverages).

· Net Weight Filling Machines: Fill based on the net weight of the product, not including the container weight, for precise product content.

Choosing the right filling machine optimizes efficiency, reduces waste, and maintains product integrity.

How to Choose the Right Filling Machine

Selecting the optimal filling equipment requires careful consideration of several factors:

1. Product Characteristics: Viscosity (thin liquid, thick paste, particulate), corrosiveness, foaming tendency, temperature sensitivity.

2. Container Type and Size: Material, shape, neck opening, volume.

3. Required Production Speed: Batches per hour, daily output goals (influences manual, semi-automatic, or automatic choice).

4. Accuracy Requirements: What level of fill precision is acceptable for your product and industry regulations?

5. Budget: Investment cost versus long-term efficiency gains.

6. Space Availability: Footprint of the machine.

7. Future Growth Plans: Scalability of the equipment.

8. Regulatory Compliance: Industry-specific standards (e.g., CE Certification, ISO Standards)

A thorough assessment of these points will guide you toward the most suitable liquid filling machine or paste filling machine for your operations.

About ZONESUN: Precision, Innovation, and Unwavering Support

Since its establishment in 2014, ZONESUN has rapidly emerged as a globally recognized leader in the design and manufacture of advanced packaging machinery. We specialize in providing comprehensive filling equipment solutions, including state-of-the-art liquid filling machines and robust paste filling machines, alongside a wide array of other packaging solutions.

At ZONESUN, our commitment to excellence is reflected in several key advantages:

· Innovation & Patented Technology: We continuously invest in research and development, resulting in proprietary technologies and patented designs that enhance machine performance, reliability, and efficiency. Our engineering team constantly pushes boundaries to deliver next-generation filling solutions.

· Customer-Centric Approach: We believe in a partnership approach. From initial consultation to post-installation support, our focus is squarely on understanding your specific production challenges and delivering a solution that precisely matches your product and operational goals. This dedication to being customer-centric has led to numerous successful customized solutions across diverse industries.

· Tailored Solutions for Optimal Performance: Unlike off-the-shelf providers, ZONESUN excels in crafting customized filling machine configurations. We analyze your product's unique viscosity, container specifications, and throughput requirements to design and deliver the most efficient and cost-effective filling equipment that seamlessly integrates into your existing line.

-

ZONESUN offers 24/7 global support and a comprehensive after-sales service system, covering installation, training, maintenance, and spare parts. This minimizes downtime and maximizes your investment. With a decade of experience, we have a proven track record of successful worldwide installations, helping businesses achieve production targets with precision and reliability.

Choosing ZONESUN means investing in a long-term partnership dedicated to your success. We deliver high-precision liquid filling machines, heavy-duty paste filling machines, and versatile filling equipment that elevate your production capabilities and drive profitability.