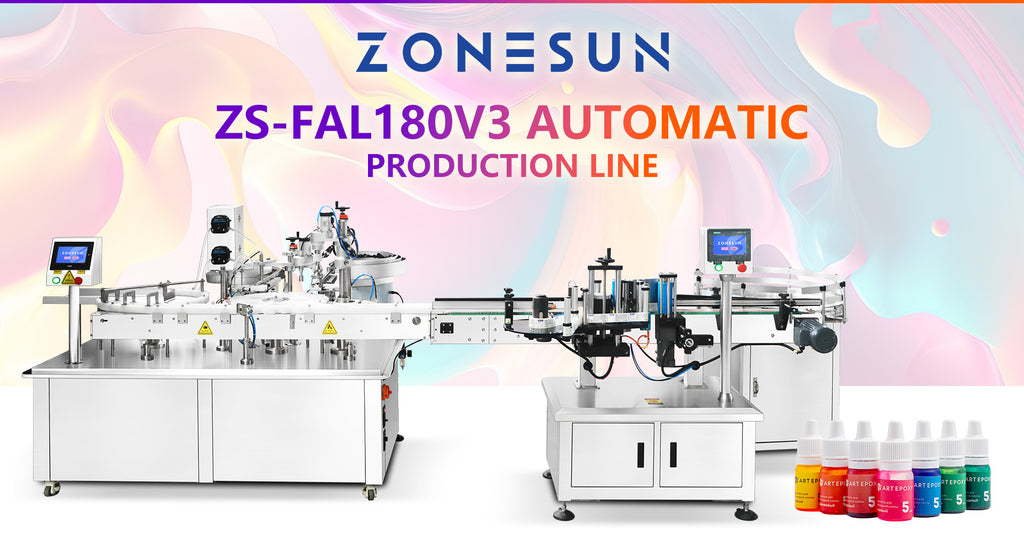

How to Streamline Automotive Coating Production with the ZONESUN ZS-FAL180V3 Bottling Line

In the competitive world of automotive detailing products, efficiency and precision are paramount. The ZONESUN ZS-FAL180V3 Car Ceramic Coating Bottling Line offers an integrated solution for businesses aiming to optimize their production processes. Designed for small bottle applications, this automated line ensures consistent filling, capping, and labeling, making it an ideal choice for manufacturers of car ceramic coatings and similar products.

Key Features of the ZS-FAL180V3 Bottling Line

1. Peristaltic Pump Filling System

At the heart of the ZS-FAL180V3 is its peristaltic pump filling mechanism. This system ensures that the liquid only contacts the tubing, maintaining product purity and preventing contamination. It's particularly suitable for handling sensitive liquids like ceramic coatings, essential oils, and cleaning agents.

2. Automatic Capping Mechanism

The integrated capping machine efficiently places and secures caps on bottles, ensuring a tight seal every time. This automation reduces manual labor and minimizes the risk of inconsistencies, enhancing overall product quality.

3. Advanced Labeling Unit

The labeling component of the ZS-FAL180V3 is designed for versatility. It can handle single-sided, double-sided, and wrap-around labeling, accommodating various bottle shapes and sizes. This flexibility allows for a professional presentation of products, aligning with brand aesthetics.ZONESUN TECHNOLOGY LIMITED

4. Compact and Modular Design

With its space-saving footprint, the ZS-FAL180V3 is suitable for facilities with limited space. Its modular design allows for easy integration into existing production lines and straightforward scalability as production demands grow.

Benefits of Implementing the ZS-FAL180V3 in Your Production Line

-

Enhanced Efficiency: Automating the filling, capping, and labeling processes reduces production time and labor costs.

-

Consistent Quality: Precision engineering ensures uniformity in every bottle, maintaining high product standards.

-

Scalability: The modular nature of the machine allows for easy upgrades and integration with additional equipment as needed.

-

User-Friendly Interface: The touch screen control panel simplifies operation, reducing the learning curve for staff.

-

Versatility: Suitable for a range of products beyond car ceramic coatings, including essential oils, cleaning agents, and more.

Applications Across Industries

While specifically designed for car ceramic coatings, the ZS-FAL180V3's versatility makes it applicable in various sectors:

-

Automotive Care Products: Waxes, polishes, and protective coatings.

-

Cosmetics: Essential oils, serums, and other liquid beauty products.

-

Household Cleaners: Disinfectants, detergents, and specialty cleaning solutions.

-

Pharmaceuticals: Liquid medications and supplements requiring precise dosing.

Conclusion

The ZONESUN ZS-FAL180V3 Car Ceramic Coating Bottling Line stands out as a comprehensive solution for businesses seeking to enhance their production efficiency and product consistency. Its advanced features, combined with a compact design, make it a valuable asset for various industries.

Explore the ZONESUN ZS-FAL180V3 Bottling Line: