Liquid Filling Machine

Liquid Filling Machine — Practical Usage and Selection Guide

What Is a Liquid Filling Machine? Types, Applications, and How to Choose the Right Filling Equipment

What Is a Liquid Filling Machine? Types, Applications, and How to Choose the Right Filling Equipment

Liquid filling machines are essential equipment in modern packaging production, ensuring accurate, hygienic, and efficient filling of liquid products into bottles, jars, cans, and pouches. Whether for beverages, cosmetics, pharmaceuticals, or household chemicals, the right liquid filling machine can significantly improve production efficiency, reduce labor costs, and enhance product consistency.

This comprehensive guide explains what a liquid filling machine is, the different types of liquid filling machines, their applications, and how to choose the best liquid filling equipment for your production needs.

What Is a Liquid Filling Machine?

A liquid filling machine is a packaging machine used to dispense precise volumes of liquid products into containers. Depending on production scale and automation level, it may operate as a standalone filler or as part of a complete automated packaging line together with capping, labeling, sealing, and inspection systems.

Core functions of a liquid filling machine include:

- Accurate and consistent filling volume or liquid level

- Stable performance in continuous production

- Reduction of leakage, dripping, and product waste

- Compliance with hygiene and safety standards

Liquid filling machinery is widely used in:

- Food and beverage

- Cosmetics and personal care

- Pharmaceuticals and healthcare

- Chemicals and household products

- Industrial and specialty liquids

Different product characteristics require different filling technologies — which makes proper machine selection especially important.

Types of Liquid Filling Machines

Liquid filling machines are categorized based on their filling principle, viscosity compatibility, and level of automation.

Gravity Liquid Filling Machines are ideal for low-viscosity, free-flowing liquids such as water, juice, alcohol, and cleaning solutions. They feature a simple structure, stable performance, and provide a cost-effective solution for basic filling needs.

Pump Liquid Filling Machines utilize gear, peristaltic, or diaphragm pumps to handle a wide range of liquids. Commonly used for cosmetics, serums, essential oils, fragrances, chemicals, and pharmaceutical liquids, these machines offer flexible volume control and strong compatibility with various liquid types.

Piston Liquid Filling Machines are designed for medium- and high-viscosity products, including shampoo, lotion, cream, gel, sauces, syrup, honey, and viscous emulsions. They provide high filling accuracy and perform exceptionally well with thicker materials.

Overflow or Level Filling Machines maintain a consistent liquid level in bottles, making them ideal for beverages, cosmetic liquids, and cleaning chemicals. These machines ensure a visually uniform bottle appearance, especially suitable for transparent containers.

Weighing Liquid Filling Machines are recommended for high-value liquids, industrial chemicals, or applications requiring strict accuracy. Using weight-based control, they deliver excellent repeatability and precise filling for demanding production environments.

Semi-Automatic vs Automatic Liquid Filling Machines

Semi-Automatic Liquid Filling Machines are ideal for small-batch production, laboratories, startups, and pilot production. They offer a lower investment cost and flexible operation, making them suitable for businesses that require precision in small-scale or experimental runs.

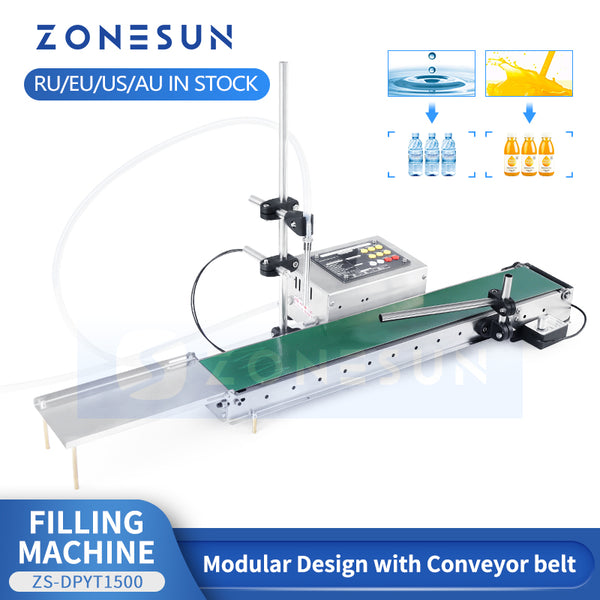

Automatic Liquid Filling Machines, on the other hand, are designed for continuous industrial production. Equipped with conveyor systems, bottle positioning devices, and multi-head filling options, these machines deliver higher efficiency, reduce labor requirements, and provide scalable capacity to meet growing production demands.

Key Features of a High-Quality Liquid Filling Machine

A professionally engineered filling machine typically includes:

- high-precision dosing system (pump / piston / servo)

- drip-proof and anti-foam filling nozzles

- stainless steel product-contact parts (SS304 / SS316L optional)

- quick-change parts for different bottle sizes

- easy-to-clean sanitary structure (CIP optional)

- stable electrical and safety control design

These features help ensure:

- durable long-term operation

- reduced changeover downtime

- compliance with international standards

How to Choose the Right Liquid Filling Machine

When selecting a liquid filling machine, consider the following:

1. Liquid characteristics

- viscosity level

- foaming behavior

- corrosiveness

- presence of particles or fibers

2. Container specifications

- bottle material and shape

- volume range and neck size

3. Production requirements

- target output capacity

- accuracy tolerance

- automation level

4. Integration needs

- capping

- labeling

- sealing

- complete packaging line compatibility

5. Certification & compliance

- CE

- ISO

- GMP or industry standards

Choosing the right filling technology helps reduce waste, improve product quality, and stabilize production performance.

Applications of Liquid Filling Machines

Liquid filling equipment is widely used in:

Food & Beverage

- water

- sauces

- condiments

- edible oil

Cosmetics & Personal Care

- lotion

- serum

- shampoo

- toner and essence

Pharmaceuticals & Healthcare

- liquid medicine

- syrups

- disinfectant solutions

Household & Chemical Products

- detergents

- cleaning liquids

- industrial chemicals

Each application requires different filling solutions depending on viscosity and production requirements.

Advantages of Automated Liquid Filling Machines

Upgrading to automated liquid filling equipment offers:

- higher filling accuracy and repeatability

- increased production efficiency

- reduced manual operation and labor cost

- improved packaging consistency and brand quality

- better hygiene and safety control

- flexible scalability for future expansion

Why Choose ZONESUN Liquid Filling Machines

ZONESUN provides a comprehensive range of liquid filling machines and customized filling solutions designed for real production environments.

Our advantages include:

- multiple filling technologies for different liquid types

- strong engineering customization capability

- modular and scalable machine design

- ISO quality management certification

- CE-certified product series

- global technical support and solution services

We deliver not only equipment, but complete packaging automation solutions.

Need Help Choosing a Liquid Filling Machine?

If you are unsure which model suits your product, our engineering team can assist with:

- application evaluation

- model recommendation

- customization options

- full production line configuration

Share your product type, viscosity range, container specifications, and expected output — and we will recommend the most suitable liquid filling solution for your production needs.